L'esperienza Ecospray nel trattamento del biogas e nella liquefazione del biometano: realizzazioni e progetti futuri.

Giorgio Copelli - Ecospray Technologies

(Atto PDF in lingua inglese)

Markets & products: marine, capabilities, renewables, industry

biogas pre-treatment & upgrading

Markets & products

Capabilities

-Research & Development

- Engineering & management

- Equipment manufacturing

- Installation supervision & commissioning

- Training

- Turn-key solutions

- After sales support

Marine

- EGCS (open loop & hybrid)

- DeNOx, PM removal

- Onboard Carbon Capture

- Methane slip removal

Renewables

- Biogas upgrading

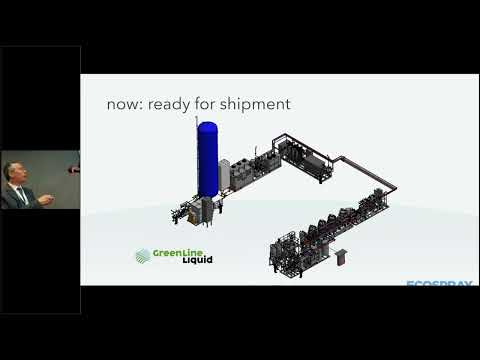

- Biomethane liquefaction

- Bio CO2 liquefaction

Industry

- Flare gas recovery (separation & liquefaction)

- Pipeline/well gas liquefaction

- Carbon Capture

- Methane slip removal

Biogas pre-treatment & upgrading

Required section to clean raw biogas from main pollutants:

- H2S,

- HCL,

- VOC

- NH3

Dryer for massive water removal, dehydrating salts or alumina to reduce dewpoint (down to -30°C)

Standard 40 feet container size, welded, wired, ready for installation

Required section to convert biogas in Biomethane (capturing CO2):

- Vacuum Pressure Swing Adsorption technology

- Low costs and consumption of the adsorbent material (synthetic zeolites)

- No hot source needed

- Low consumption thanks to the absence of biogas compression (~0.2 kWh/Nm3 biogas)

- High tolerance on biogas impurities fluctuations.

Continua nel PDF

Capabilities

-Research & Development

- Engineering & management

- Equipment manufacturing

- Installation supervision & commissioning

- Training

- Turn-key solutions

- After sales support

Marine

- EGCS (open loop & hybrid)

- DeNOx, PM removal

- Onboard Carbon Capture

- Methane slip removal

Renewables

- Biogas upgrading

- Biomethane liquefaction

- Bio CO2 liquefaction

Industry

- Flare gas recovery (separation & liquefaction)

- Pipeline/well gas liquefaction

- Carbon Capture

- Methane slip removal

Biogas pre-treatment & upgrading

Required section to clean raw biogas from main pollutants:

- H2S,

- HCL,

- VOC

- NH3

Dryer for massive water removal, dehydrating salts or alumina to reduce dewpoint (down to -30°C)

Standard 40 feet container size, welded, wired, ready for installation

Required section to convert biogas in Biomethane (capturing CO2):

- Vacuum Pressure Swing Adsorption technology

- Low costs and consumption of the adsorbent material (synthetic zeolites)

- No hot source needed

- Low consumption thanks to the absence of biogas compression (~0.2 kWh/Nm3 biogas)

- High tolerance on biogas impurities fluctuations.

Continua nel PDF

Fonte: mcTER Biometano-Biogas-Biomasse - Milano giugno 2024

Settori: Ambiente, Biocarburanti, Bioenergia, Biogas, Biomasse, Biometano, Combustibili, Efficienza energetica industriale, GAS, Rinnovabili

- BRUGG Pipe Systems

- CIB - Consorzio Italiano BioGas

English

English